Forming technology

Umformtechnik Stade has over 30 years of experience in sheet metal forming. Our innovative strength and constant development are shown not only by almost 30 patents, but also by our long-standing customer relationships.

Our core competence is the forming by:

Umformtechnik Stade has the experience of over 30 years of sheet metal forming. Our innovative strength and constant development are demonstrated not only by the nearly 30 patents but also by our long-standing customer relationships.

Our core competence is the forming by:

In forming technology, it is necessary to know the limits of the technical manufacturing processes in order to reduce costs and manufacture economical products.

Feel free to contact us, we are looking forward to your challenge.

… and much more In forming technology, it is necessary to know the limits of the technical manufacturing processes in order to reduce costs and manufacture economical products.

Feel free to contact us, we are looking forward to your challenge.

Tool making

Umformtechnik Stade is able to manufacture tools. From the concept phase to the design and manufacturing of the tools, we cover all areas and can therefore also produce prototype tools very quickly or make adjustments if required.

Examples for different applications:

Umformtechnik Stade is able to manufacture tools. From the concept phase to the design and manufacturing of the tools, we cover all areas and can therefore also produce prototype tools very quickly or make adjustments if required.

Examples for different applications:

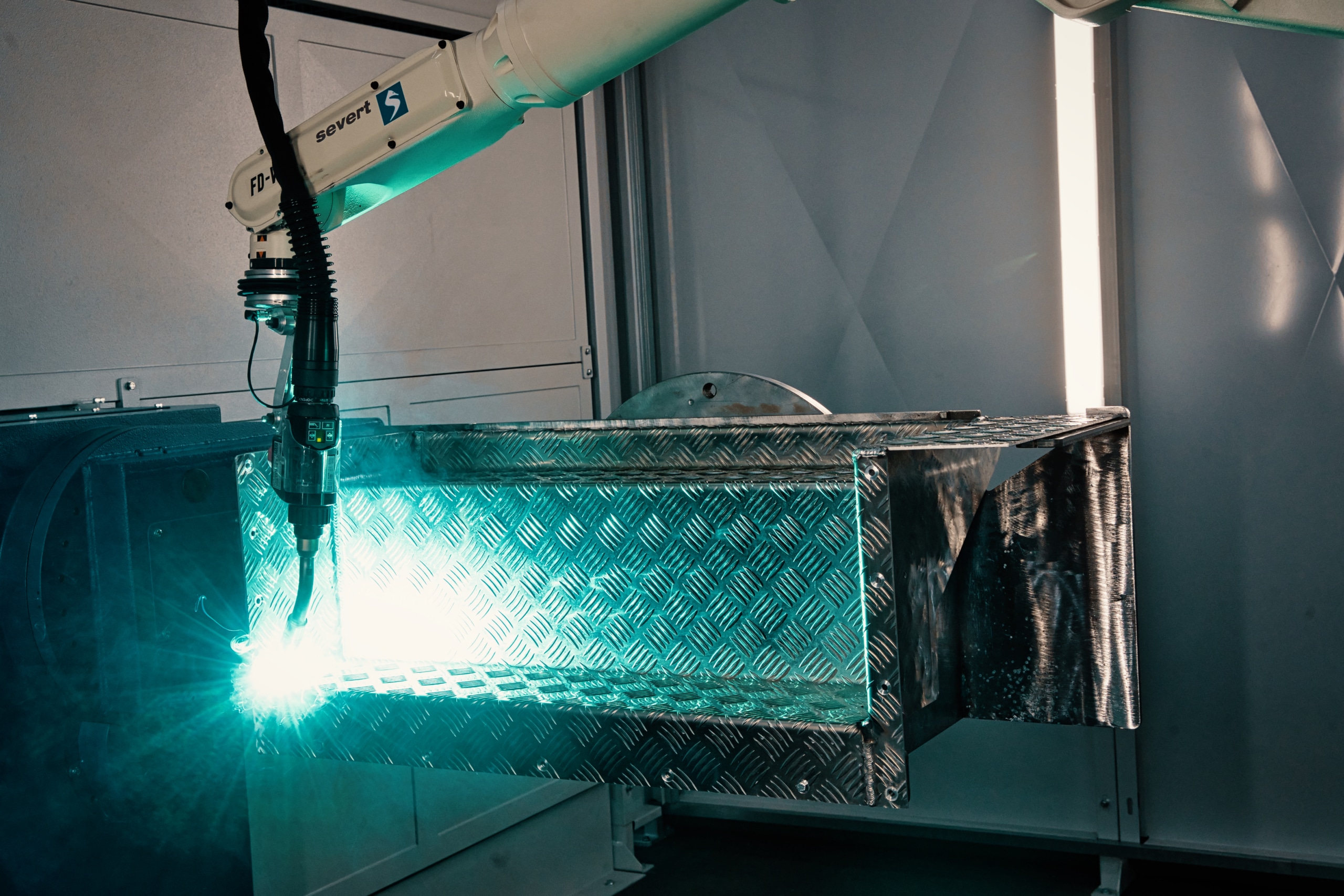

Welding technology

Umformtechnik Stade is a registered and certified welding company for rail vehicles according to DIN EN 15085 CL1. In addition, we have decades of experience in robotic welding technology and partially mechanized joining processes. We focus particularly on the training of our welders and continuous education to ensure the highest level of quality.

Our competencies:

Umformtechnik Stade is a registered and certified welding company for rail vehicles according to DIN EN 15085 CL1. In addition, we have decades of experience in robotic welding technology and partially mechanized joining processes. We focus particularly on the training of our welders and continuous education to ensure the highest level of quality.

Our competencies:

We are also always exploring new approaches in welding technology. Thus, CMT technology for thin sheet welding is also an integral part of our portfolio.

We maintain solid connections with our customers and this also applies to our welding technology.

We are also always exploring new approaches in welding technology. Thus, CMT technology for thin sheet welding is also an integral part of our portfolio.

We maintain solid connections with our customers and this also applies to our welding technology.

Consulting

As a specialist in forming technology and processing of metal products, we are your key contact from the concept phase to the manufacturing process and beyond.

As a specialist in forming technology and the processing of metal products, we are your central contact from the concept phase to the manufacturing process and beyond.

„We transform your concepts into economical products.“

After the definition of components, we start with the computer-aided tool development. Modern tools, networking with partners and the use of simulations (FEM) shorten this phase and lead to the first prototypes in just a few steps. Afterwards, we carry out final changes together and start with the series production of your products.

After the component definition we start with the computer-aided tool development. Modern tools, networking with partners and the use of simulations (FEM) shorten this phase and lead to the first prototypes in just a few steps. Afterwards, we carry out final changes together and start with the series production of your products.